Industrial Safety

INERCO implements advanced solutions and services in Process Safety Management (PSM), Asset Integrity and Emergency Management, aiming to achieve the highest levels of safety in the design, engineering and operation of industrial facilities to ensure the business and operation continuity.

INERCO’s advanced solutions and services in Process Safety Management (PSM) and Asset Integrity throughout the company life cycle are designed and developed to get Design, Operation and Maintenance integrity.

Juan Santos Remesal

Industrial Safety Division Director | Manager Reach Integra

Pilar Ojeda Rodríguez

Industrial Safety Division ManagerTOOLS & SOLUTIONS FOR THE INTEGRAL SAFETY MANAGEMENT IN A PROJECT LIFE CYCLE:

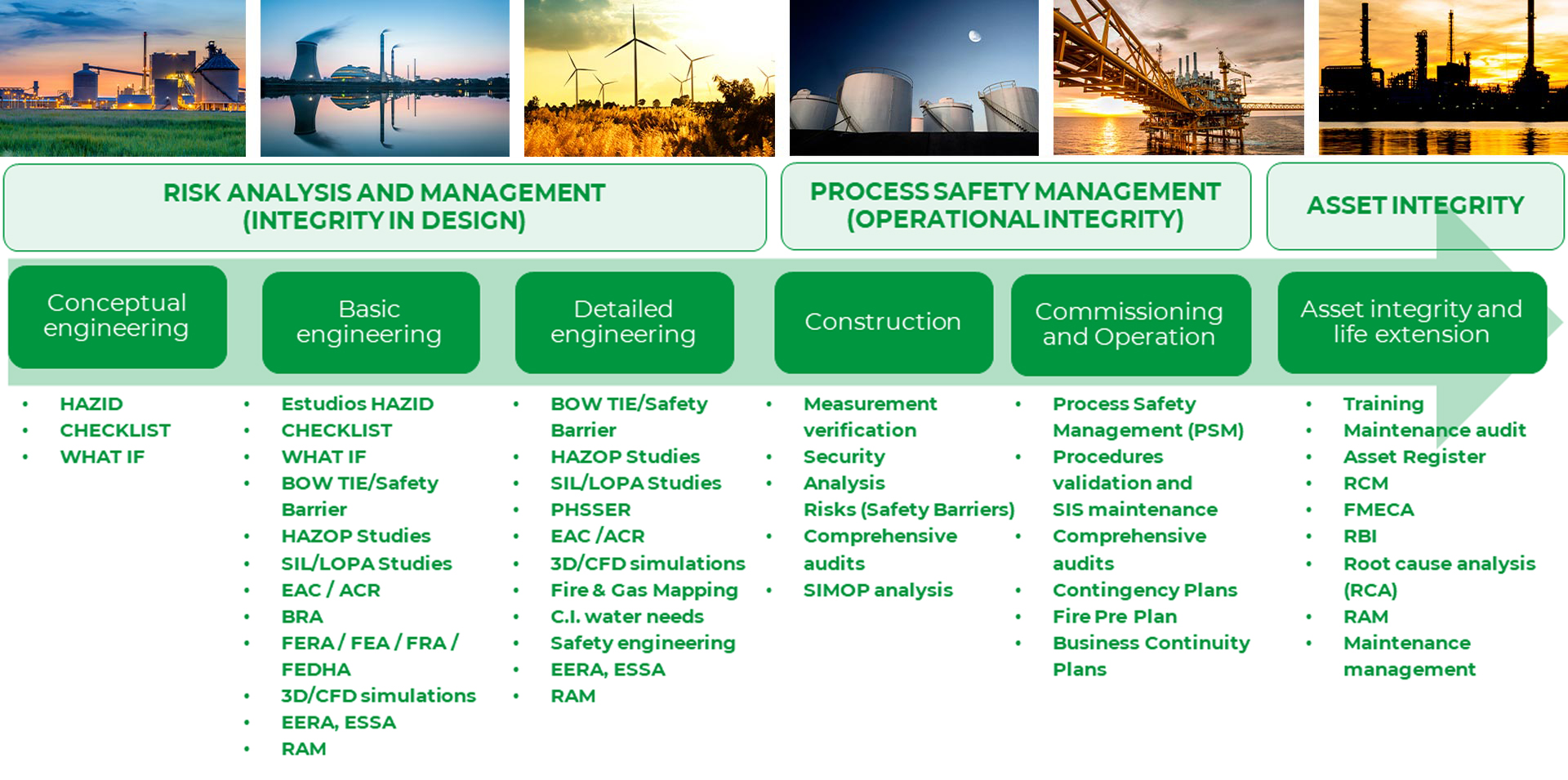

Our solutions applied to each engineering project phase will guarantee optimal hazard identification, risk management and safety engineering.

RISK ANALYSIS (PHA) & FUNCTIONAL SAFETY (SIS/SIL)

INTEGRITY IN DESIGN – RISK ASSESSMENT AND MANAGEMENT

INERCO applies advanced tools for risk identification, assessment and management to define an intrinsically safe design, in which the risks are as low as possible and safety levels increase.

Proactive risk management entails noteworthy safety benefits throughout the entire life cycle of an industrial facility, such as:

BENEFITS AND RESULTS

Identify dangerous situations, their consequences and their probability.

Define prevention and mitigation measures.

Guarantee risk management in a systematic way.

Reduce or minimize the occurrence of industrial accidents.

Improve, enhance and increase the capacity to respond to emergency situations.

Juan Santos Remesal

Industrial Safety Division Director | Manager Reach Integra

Pilar Ojeda Rodríguez

Industrial Safety Division ManagerRISK ASSESSMENT AND MANAGEMENT SERVICES

Process Risk Analysis (PHA)

- HAZID (HAZard IDentification Analysis).

- CHECKLIST.

- ‘WHAT IF’ analysis.

- HAZOP (HAZard & OPerability Analysis).

- LOPA analysis (Layer of Protection Analysis).

- FMEA (Failure Mode&Effects Analysis).

- BOW-TIE/Safety Performance Standars.

- PHSSER.

- SIMOP.

- RAMS.

Functional safety SIL / SIS (Safety Integrity Level)

- SIL index assignment.

- Verification of the conceptual design of Security Instrumented Systems (SIS).

- Development of SRS (Safety Requirement Specifications).

- SIS validation and maintenance procedures.

Quantitative risk analysis. Modeling of effects and consequences

- SEVESO Safety Reports.

- Consequences Analysis (EAC).

- Quantitative Risk Analysis (QRA).

- Fire and explosion risk assessment (FERA / FEA / FRA / FEDHA).

- Building Risk Analysis (BRA).

- Thermal radiation studies on equipment and structures. Firefighting water needs.

- Analysis of overpressures in equipment and structures due to explosion.

- 3D/CFD fluid dynamic modeling.

- Fire & Gas Mapping. Conceptual design of the F&G system.

- Escape, evacuation and rescue studies (EERA and ESSA).

- Exhaust gas and smoke dispersion analysis (GDSI).

Analysis of environmental and natural risks

- Environmental Risk Assessment and determination of financial guarantees.

- Air Pollutant Risk Assessment.

- Accidental spills Risk Assessment.

- Risk Assessment and Combating of accidental marine pollution.

- Natural hazards Risk Assessment (Floods, Forest Fires, Earthquakes, Tsunamis).

- Environmental Risk Maps.

PROCESS SAFETY MANAGEMENT (PSM)

OPERATIONAL INTEGRITY – PROCESS SAFETY MANAGEMENT (PSM)

We help companies to effectively implement the different elements and pillars of the Process Safety Management System (PSM).

We design the optimal Roadmap from an exhaustive initial diagnosis of their situation, benchmarking with their sector and considering their strategic security objectives.

BENEFITS AND RESULTS

Increase the intrinsic safety of processes in their design, operation and maintenance.

Guarantee greater availability of the facilities and the production process.

Reduce repair costs, lost profits and insurance.

Prioritize corrective actions and economic investments.

Achieve operational excellence and in particular with regard to industrial safety.

Juan Santos Remesal

Industrial Safety Division Director | Manager Reach Integra

Pilar Ojeda Rodríguez

Industrial Safety Division ManagerPSM. LIFE CYCLE OF INDUSTRIAL PLANTS

ELEMENTS PSM: ENERGY INSTITUTE

RELIABILITY & MAINTENANCE (ASSET INTEGRITY)

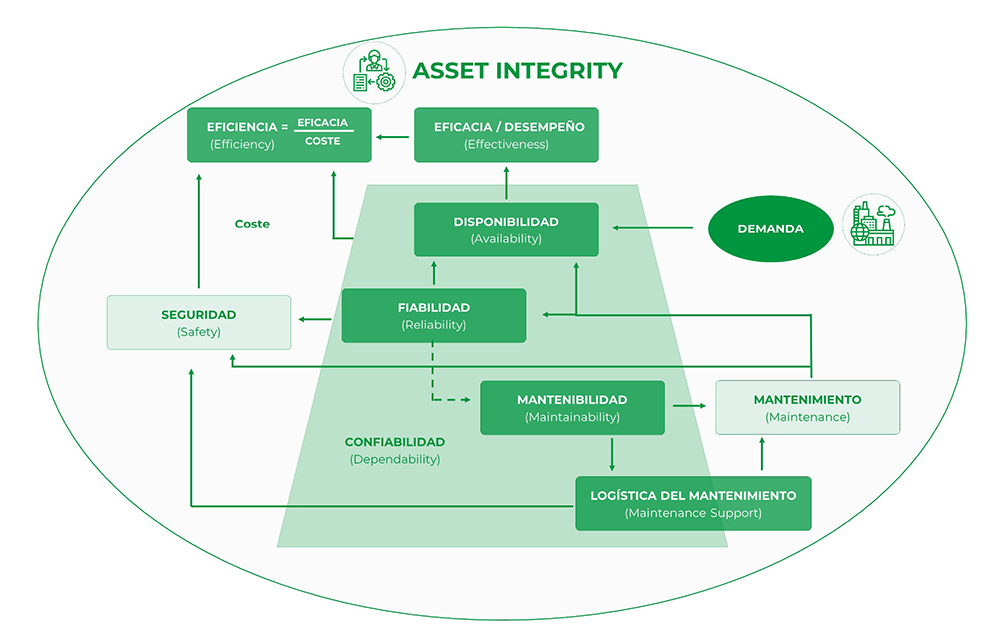

ASSET INTEGRITY – RELIABILITY AND MAINTENANCE

We develop Optimized Reliability and Maintenance Strategies in equipment, assets and safety barriers.

INERCO’s industrial asset integrity management model is based on a comprehensive view of the operational characteristics that contribute to the efficient exploitation of the physical assets of an industrial facility and to their measurement, analysis and optimization during the different phases of the life cycle of these assets. For this purpose, the most appropriate methods and techniques are applied in each specific case, so that the following objectives are achieved in a practical, objective and profitable manner.

BENEFITS AND RESULTS

Maximize the reliability and availability of the equipment.

Increase asset efficiency and operating results.

Optimize maintenance planning, inspection costs.

Improve the security of facilities by reducing risk.

Juan Santos Remesal

Industrial Safety Division Director | Manager Reach Integra

Pilar Ojeda Rodríguez

Industrial Safety Division ManagerWe rely on our partner:

ASSET INTEGRITY. TOOLS AND BENEFITS CONCEPTUAL MAP

The approach and methodology of the integrity and services management model offered by INERCO allows optimizing the Integrity Management of Industrial Assets, applying the different tools independently, if the reinforcement of a specific element is necessary, or globally, in order to achieve maximum efficiency in the different activities execution.

INDUSTRIAL ASSETS INTEGRITY MANAGEMENT MODEL

EMERGENCY MANAGEMENT

INTERNAL EMERGENCY PLANS

We design and implement effective and operational internal emergency plans and Emergency Systems, focused on mitigating and minimizing the consequences. We develop Business Continuity Plans to reestablish the continuity of the operation and the business.

INERCO comprehensively approaches the Self-Protection and Emergency strategy, from the design of emergency plans to their implementation and training, as well as management and support tools and services during the emergency.

EMERGENCY MANAGEMENT SERVICES

Emergency Plans

- Chemical Emergencies (Seveso).

- Emergency Plan.

- Environmental Emergencies.

- Ports Internal Emergency Plans and Accidental Marine Pollution.

- Territorial Emergency Plans and Special Risks Civil Protection.

- Fire Pre Plan and Advanced Emergency Procedures.

- Dangerous Goods Transport (ADR / RID). Safety Conselor.

Implementation of emergency plans.

- Responsiveness diagnosis.

- Training and education.

- Practical training in Emergencies and Fire Fighting. SGI.

- Emergency simulator.

Emergency management and support systems: SIGEM, CARECHEM / CHEMDATA and FACT24

- SIGEM: Emergency Management Information System.

- CARECHEM/CHEMDATA: INERCO provides an emergency response service through the distribution of the services Carechem 24 and Chemdata, thanks to an agreement reached with the British National Chemical Emergency Centre (NCEC) to be its official distributor in Spain and South America.

Carechem 24 provides a 24 hours emergency response helpline available in more than 40 languages, allowing to cover emergencies worldwide. All calls are responded by highly qualified chemists capable of responding to any emergency in less than five minutes.

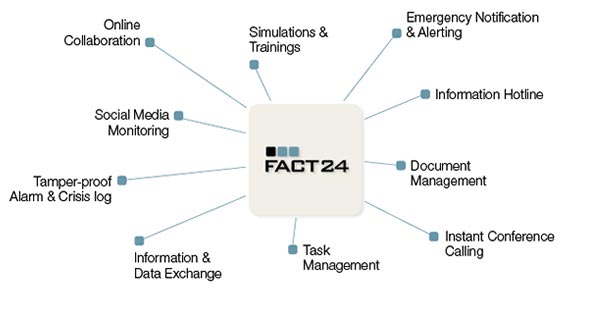

Chemdata is a database developed by emergency responders containing information on more than 10,000 substances and 40,000 mixtures. It is available on a computer based version as well as for mobile devices, such as Android and Apple (Chemdata Pocket). In case of emergency, as the information is available off-line (no internet connection is required), the right information is always available. - FACT 24: INERCO is an Authorized Partner for representing the F24 company. FACT24 is an innovative, efficient, professional service for alerting and crisis management. With FACT24 you can manage and handle critical situations more reliably and effectively – from beginning to end. You benefit from a faster return to normal operations, allowing you to avoid major losses or follow-up costs.

In an emergency or crisis situation, FACT24 allows you to quickly notify and alert all relevant individuals, hold impromptu telephone conferences, or open an information hotline for local residents and the media on short notice. Additionally, you can exchange information and files with all of the teams involved in real time.

Juan Santos Remesal

Industrial Safety Division Director | Manager Reach Integra

Pilar Ojeda Rodríguez

Industrial Safety Division ManagerCOMBATING MARINE POLLUTION BY HYDROCARBONS

COMBATING MARINE POLLUTION BY HYDROCARBONS

INERCO helps our clients to implement Comprehensive Systems for the Response and Combat Marine Pollution by Hydrocarbons, monitoring their assets and risks, characterizing and modeling hydrocarbon spills and supporting their Operational Plans to Combat Marine Pollution, aiming to minimize the consequences and damage to the environment.

We have extensive experience in advising hydrocarbon operators and administration emergency response services.

BENEFITS AND RESULTS

Response system tailored to customer needs and needs.

Continuous monitoring 24 x 7 x 365.

Reliability and precision.

Detection in early phases of the emergency and activation of the response.

Intervention decision-making based on actual emergency data and its considerations in predictions.

Ability to predict evolution and monitoring.

Identification of the source of the contamination.

Significant cost savings compared to other asset monitoring solutions such as flights using airplanes.

Endorsed by the experience of more than 20 years in Remote Sensing and Advice in the Fight Against Marine Pollution.

Juan Santos Remesal

Industrial Safety Division Director | Manager Reach Integra

Pilar Ojeda Rodríguez

Industrial Safety Division ManagerWe rely on our partner:

SERVICES TO COMBAT MARINE OIL POLLUTION

Advanced technical advice

- Risk Analysis and advanced detailed modelling of the behaviour of chemicals spilt at sea.

- Evaluation and diagnosis of the response capacity.

- Technical advice on the management of the means of struggle.

- Specific procedures to combat Marine Pollution.

- Implementation of specific procedures to combat Marine Pollution.

- Specialized advice in emergencies.

- Training.

Automatic satellite monitoring of hydrocarbon spills (EOS Viewer)

EOS Viewer.

Observation and Characterization of events through image processing using Artificial Intelligence.

COMPREHENSIVE SOLUTION IN COMBATING MARINE POLLUTION

BUSINESS CONTINUITY

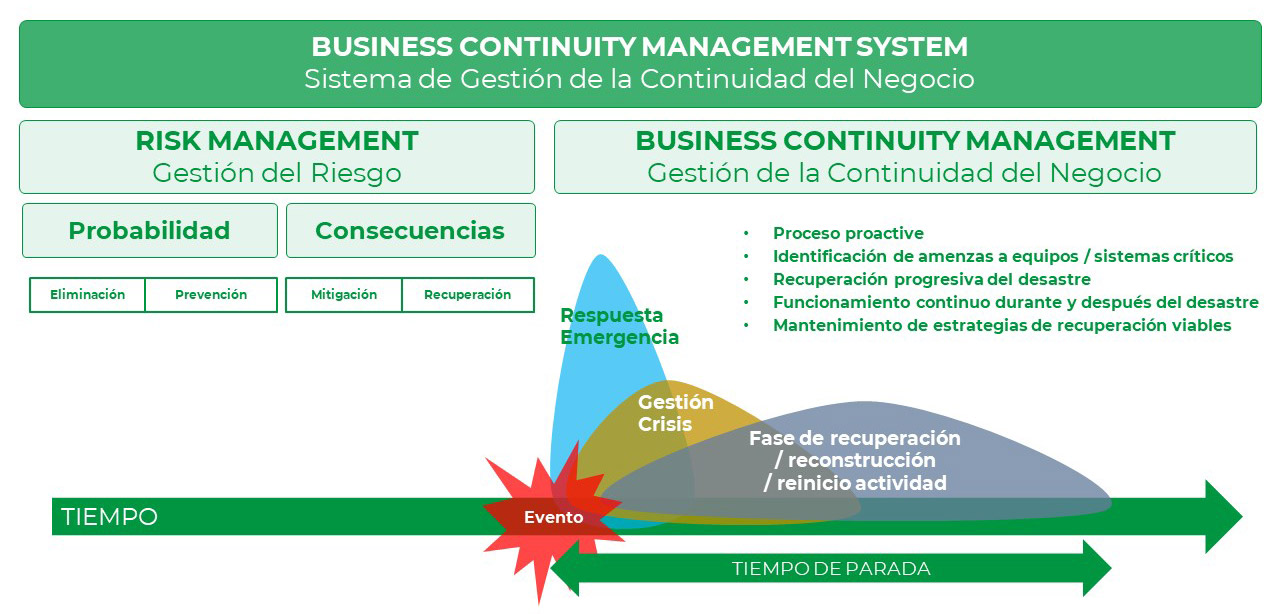

BUSINESS CONTINUITY STRATEGY

INERCO helps and advises the Corporate Management and Risk Departments to develop and implement Business Continuity Management System (ISO 22301).

BENEFITS AND RESULTS

Establish the strategic line and commitments of the organization to ensure continuity.

Know the risks of their activities, their impact on the business and their acceptability criteria from a business continuity point of view.

Implement an orderly response through the Business Continuity Plan to reduce / minimize the disruption time of your critical activities.

Maximize the resilience of industrial facilities against disruptive elements.

Juan Santos Remesal

Industrial Safety Division Director | Manager Reach Integra

Pilar Ojeda Rodríguez

Industrial Safety Division ManagerRESPONSE IN EMERGENCY & BUSINESS CONTINUITY

BUSINESS CONTINUITY SERVICES

INERCO has extensive experience and deep knowledge of the risks to business impact. We comprehensively address the development of all phases of business continuity in its design, implementation and maintenance:

Design of a BCMS (business continuity management system)

- Establish parts of the organization involved.

- Establish BCMS requirements based on legislative requirements and business objectives.

- Identify products / services and related activities within the scope of the BCMS.

- Reconcile with needs and interests of interested parties.

- Define the scope of the BCMS based on the size and complexity of the organization.

BCMS Policy Establishment and Planning

- Establish business continuity policy.

- Establish roles, responsibilities and competencies.

- Appoint staff responsible for the development of the BCMS with authority and competencies for its development.

- Ensure BCMS objectives are established.

- Define risk acceptability criteria.

- Define business continuity objectives and plans.

- Assign resources.

- Communication.

Risk analysis

- Identify risks that can interrupt the priority activities of the organization in a systematic way.

- Assess what risks involve business interruption and require treatment.

- Identify treatment to apply based on the organization’s continuity and risk appetite objectives.

Business impact analysis

- Identify risks that can interrupt the priority activities of the organization in a systematic way.

- Assess what risks involve business interruption and require treatment.

- Identify treatment to apply based on the organization’s continuity and risk appetite objectives.

Business Continuity Plan (BCP)

- Establish a business continuity strategy based on the results of the RA, BIA and risk acceptance criteria (risk appetite) for each scenario.

- Define the necessary resources to implement the strategy.

Training and testing

- Specify training plan.

- Define test schedule.

Design and implementation of procedures

- Arrange the response structure to the incident.

- Establish alarm and communication systems.

- Design the business continuity plan for each scenario.

Evaluation and improvement

- Audits and reviews plan.

- Change management.

PROTECTION AND RESILIENCE OF CRITICAL ENTITIES

STRATEGY FOR THE PROTECTION AND RESILIENCE OF CRITICAL ENTITIES

At INERCO, we help and advise companies that operate essential services to comply with the future Law on the Protection and Resilience of Critical Entities, ensuring their ability to prevent, resist and recover from incidents that affect the provision of essential services by strengthening their resilience.

RESULTS AND BENEFITS

Anticipate vulnerabilities and reduce operational risks to ensure service continuity.

Establish the organisation's strategic line and commitments to ensure continuity, protecting its reputation and social trust.

Ensure regulatory compliance and obtain official certifications, providing competitive advantage and credibility in the market.

Minimise the impact of disruptions through clear protocols, optimising resources and reducing crisis-related costs.

Strengthen organisational culture and incident response capabilities, contributing to comprehensive resilience against physical, technological and climatic threats.

Juan Santos Remesal

Director División Seguridad Industrial | Director Gerente Reach Integra

Pilar Ojeda Rodríguez

Jefa del Departamento de Seguridad IndustrialRESILIENCE PROTECTION SERVICES FOR CRITICAL ENTITIES

At INERCO, we have extensive experience and in-depth knowledge of the risks that can impact the business of critical entities. We take a comprehensive approach to the development of all phases of business continuity in its design, implementation and maintenance:

Comprehensive Risk Assessment

- Conducting analysis of physical, operational and organisational threats.

- Identifying sectoral interdependencies.

Design of Resilience Plans

- Proposing and implementing technical, organisational and security measures to ensure resilience.

- Establish response and recovery protocols for the consequences of incidents.

- Establish protocols for reporting incidents that disrupt the provision of essential services.

Preparation for National Certification

- Assess the requirements of the National Certification Scheme before the competent authority.

- Provide advice on compliance with the National Certification Scheme.

Incident Management and Communication

- Prepare incident reports for the Secretary of State for Security.

Education and Training

- Establish awareness programmes, drills, and testing of critical personnel.

Evaluation and Improvement

- Plan audits and reviews.

- Change management.

Comprehensive solutions in relation to the safety and / or protection of chemical products.

WEBINARS ON INDUSTRIAL SAFETY TOPICS

- 26 October, 2021

- 13 October, 2021

- 01 October, 2021

- 08 June, 2021

- 08 April, 2021