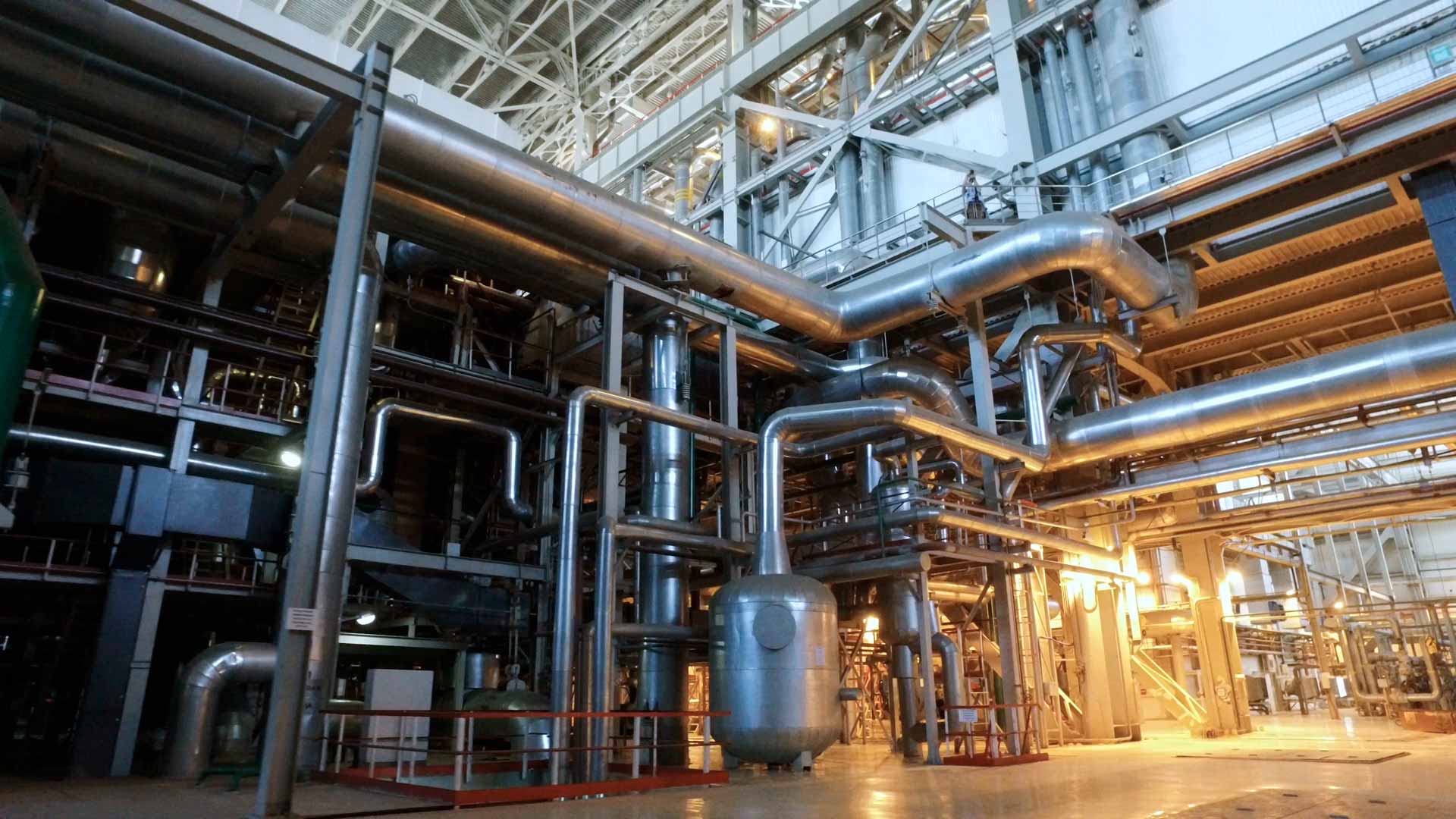

INERCO al Servicio del Desarrollo Industrial Sostenible

Tecnología Energética |

Tecnología Ambiental |

Ingeniería |

Medio Ambiente |

Seguridad y Prevención |

Proyectos en

70

países

Más de

650

profesionales

Oficinas en

9

países

Proyectos

en 70

países

Más de

650

profesionales

Oficinas

en 9

países

Compañía global aliada de la industria para el desarrollo industrial sostenible

Compañía global aliada de la industria para el desarrollo industrial sostenible

INERCO, soluciones integrales para el desarrollo industrial sostenible

INERCO, soluciones integrales para el desarrollo industrial sostenible

INERCO cuenta con oficina propia en Brasil, Chile, Colombia, España, India, México, Perú, Portugal y USA, y proyectos ejecutados desde 1984 en más de 70 países, aval para nuestros clientes en áreas de trabajo esenciales, que se ven reforzadas por la calidad, rigor y solvencia de nuestro trabajo.

¿Hablamos?

Nuestros

Partners

Colaborando con líderes de la industria por un desarrollo sostenible.

Nuestros

Partners

Colaborando con líderes de la industria por un desarrollo sostenible.

Nuestros

Partners

Colaborando con líderes de la industria por un desarrollo sostenible.